MIL-PRF-83421/1D

REQUIREMENTS:

Case material: Nonmagnetic (end seals may be of magnetic material).

Leads:

.500 inch (12.70 mm) and smaller case diameters: Composition W and final finish 32 of MIL-STD-1276.

Composition N and final finish 32 of MIL-STD-1276 may be furnished when specified in contract or order

(see MIL-PRF-83421 ordering data).

.562 inch (14.27 mm) and larger case diameters: Composition C and final finish 32 of MIL-STD-1276.

Capacitance value: See table I.

Capacitance tolerance: See table I.

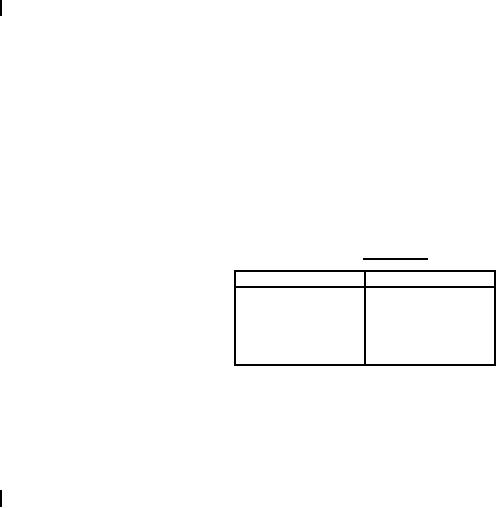

TABLE II. DC ratings.

Styles

Volts, dc

30

CRH01, CRH06

50

CRH02, CRH07

100

CRH03, CRH08

200

CRH04, CRH09

400

CRH05, CRH00

Operating temperature range: -65C to +100C; derate linearly from +100C to 50 percent of rated voltage at

+125C.

Failure rate (FR) level: M (1.0%), P (0.1%), R (0.01%), and S (0.001%) (established at dc rated voltage at

+100C ).

Burn-in (styles CRH01 through CRH05 only): 140 percent minimum of dc rated voltage shall be applied for 48

hours minimum at +125C +4C, -0C.

Thermal shock: Method 107 of MIL-STD-202, test condition B.

Styles CRH01 through CRH05: 10 cycles.

Styles CRH06 through CRH00: 5 cycles.

Seal: Method 112 of MIL-STD-202, test condition C, procedure IIIa with the following exceptions and details: A

bomb pressure of 45 5 lbf/in (gage), exposure time of 1 hour +1 hour, -0 hour, and dwell time of 1 hour

2

-6

3

-5

maximum. The reject limit for styles CRH01 through CRH05 is R1 = 1 X 10 atm cm /s and R1 = 1 X 10 atm

3

cm /s for styles CRH06 through CRH00. Upon completion of test condition C, perform either test condition A,

test condition B with mineral oil, or test condition D.

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business