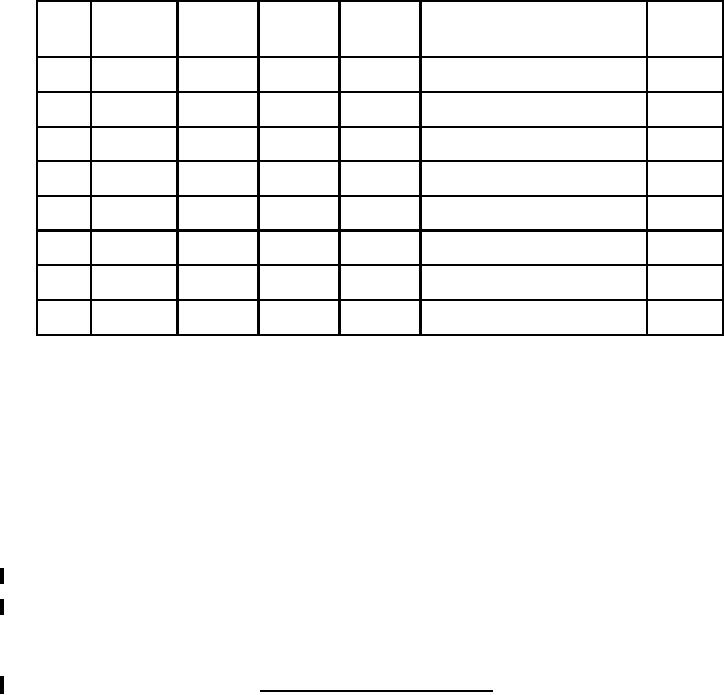

MIL-PRF-55365/4J

P

W

H

L

H2

Case

W2

+.010 (0.25)

size

min

± .015 (0.38) ±.015 (0.38) ±.015 (0.38)

- .005 (0.13)

A

.100 (2.54)

.050 (1.27)

.050 (1.27)

.030 (0.76)

.050 ±.005 (1.27±.013)

.030 (0.76)

B

.150 (3.81)

.050 (1.27)

.050 (1.27)

.030 (0.76)

.050 ±.005 (1.27±.013)

.030 (0.76)

C

.200 (5.08)

.050 (1.27)

.050 (1.27)

.030 (0.76)

.050 ±.005 (1.27±.013)

.030 (0.76)

D

.150 (3.81)

.100 (2.54)

.050 (1.27)

.030 (0.76)

.095+.005,-.010 (2.41+0.13, -0.25)

.030 (0.76)

E

.200 (5.08)

.100 (2.54)

.050 (1.27)

.030 (0.76)

.095+.005,-.010 (2.41+0.13, -0.25)

.030 (0.76)

F

.220 (5.59)

.135 (3.43)

.070 (1.78)

.030 (0.76)

.130±.005 (3.30±0.13)

.040 (1.02)

G

.265 (6.73)

.110 (2.79)

.110 (2.79)

.050 (1.27)

.105±.005 (2.67±0.13)

.060 (1.52)

H

.285 (7.24)

.150 (3.81)

.110 (2.79)

.050 (1.27)

.145+.005. -.020 (3.68 +0.13, -0.51) .060 (1.52)

NOTES:

1. Dimensions are in inches.

2. Metric equivalents are given for general information only.

3. Metric equivalents are in parentheses.

4. These capacitors are designed for mounting by dip soldering, thermo-compression bonding, reflow soldering, or

other conventional means.

5. The anode (+) terminal shall be identified by a marking on the case.

6. The termination width (W2) shall be maintained to the top of the solderable area.

7. Solderable surfaces are only those surfaces designated as such. Termination edges are not considered

solderable.

8. When solder coated terminations are required, add an additional .015 inch (0.38 mm) to the above listed

tolerances for "L", "H", "P", and "W2" for each case size.

9. Shown with optional glue pad. At the option of the manufacturer, a glue pad between the solderable surfaces

may be substituted.

FIGURE 2. Style CWR09 (molded chip) capacitors Continued.

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business