MIL-PRF-39014/2L

NOTES:

1. Dimensions are in inches.

2. Metric equivalents are given for general information only.

3. Unless otherwise specified, tolerance is ±.010 inch (0.25 mm).

4. Lead length may be a minimum of .625 inch (15.88 mm) for use in tape and reel automatic insertion

equipment, when specified.

5. Lead diameter shall be .023 inch (0.58 mm) to .029 inch (0.74 mm).

6. Optional standoffs shall be of triangular shape so that the standoff will provide line contact with the surface

upon which the capacitor is mounted.

*

7. Thickness of standoffs shall be a minimum of .075 inch (1.90 mm) to a maximum of the actual thickness of

the capacitor body.

8. Insulation coating shall not extend more than .018 inch (0.46 mm) along lead wires.

9. At the option of the user, the standoff configuration may be substituted as a replacement for the nonstandoff

configuration of the same style.

10. For flush mounting .078 inch (1.98 mm), printed circuit hole diameter is required to clear shoulder.

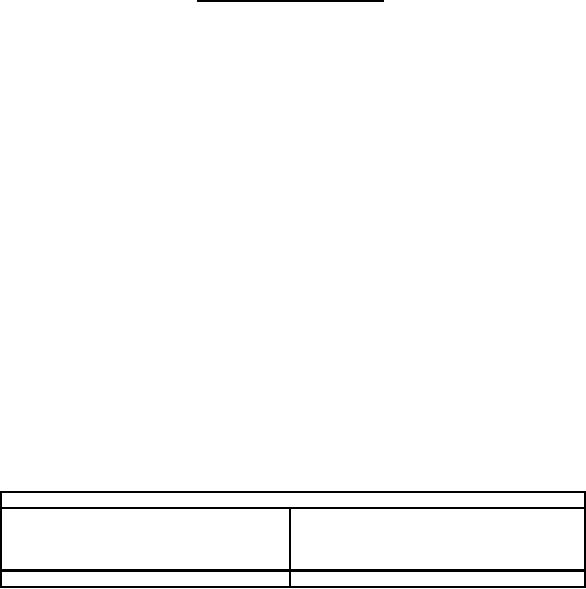

FIGURE 1. Dimensions and configurations - Continued.

REQUIREMENTS:

Dimensions and configuration: See figure 1.

Case type: Molded.

Capacitance value: See table I.

Capacitance tolerance: See table I.

Operating temperature range: -55°C to +125°C.

Voltage rating: See table I.

Radiographic inspection (failure rate level 'S' (0.001 percent/1,000 hours only)): In accordance with

MIL-PRF-39014.

Dissipation factor: Not more than 2.5 percent.

Dielectric withstanding voltage:

Body insulation: Shall be able to withstand 1,300 volts between leads and case.

Insulation resistance (IR):

At 25°C: Not less than 100,000 megohms or 1,000 megohm-microfarads, whichever is less.

At 125°C: Not less than 10,000 megohms or 100 megohm-microfarads, whichever is less.

Voltage-temperature limits: In accordance with MIL-PRF-39014.

Capacitance change with reference to +25°C

Step E through step G of MIL-PRF-39014,

Step A through step D of MIL-PRF-39014,

voltage-temperature limit cycle table

voltage-temperature limit cycle table

Bias = rated voltage

Bias = 0 volts

±15 percent

+15 percent, -25 percent

Immersion:

IR: Not less than 50 percent of initial 25°C requirement.

2