MIL-C-18312G

APPENDIX A

PROCEDURE FOR QUALIFICATION INSPECTION

A.1. SCOPE

A.1.1 Scope. This appendix details the procedure for submission of samples for qualification inspection of

capacitors covered by this specification. The procedure for extending qualification of the required sample to other

capacitors covered by this specification is also outlined herein. This appendix is a mandatory part of the

specification. The information contained herein is intended for compliance.

A.2 APPLICABLE DOCUMENTS. This section is not applicable to this appendix.

A.3. SUBMITTAL PLANS

A.3.1 Single PIN. The following details shall apply:

a. Sample size: As specified in table V.

b. Sampling criteria: Sample units of the same style, rated voltage, capacitance tolerance, operating

temperature range, insulating sleeve material (when applicable), terminal, case material and finish shall be

submitted.

c. Limits of coverage: Qualification coverage shall be extended to all lesser capacitance values and broader

capacitance tolerances in the same rated voltage. Circuit diagram 1 will qualify circuit diagram 3.

A.3.2 Combined PIN. The following details shall apply:

a. Sample size: As specified in table A-I.

b. Sampling criteria: Sample units of the same operating temperature range, capacitance tolerance, insulating

sleeve material (when applicable), case material, and finish may be submitted.

c. Limits of coverage: Qualification will be extended to all broader capacitance tolerances, all capacitance

values and rated voltages between the values and ratings submitted in the same temperature range.

Circuit diagram 1 will qualify circuit diagram 3.

A.3.3 Impregnant. Two hundred cubic centimeters of each impregnant used in the specimens for which approval

is sought shall be submitted. On subsequent submissions, an impregnant that has successfully withstood the

flashpoint of impregnant test (see 4.7.17) need not be submitted.

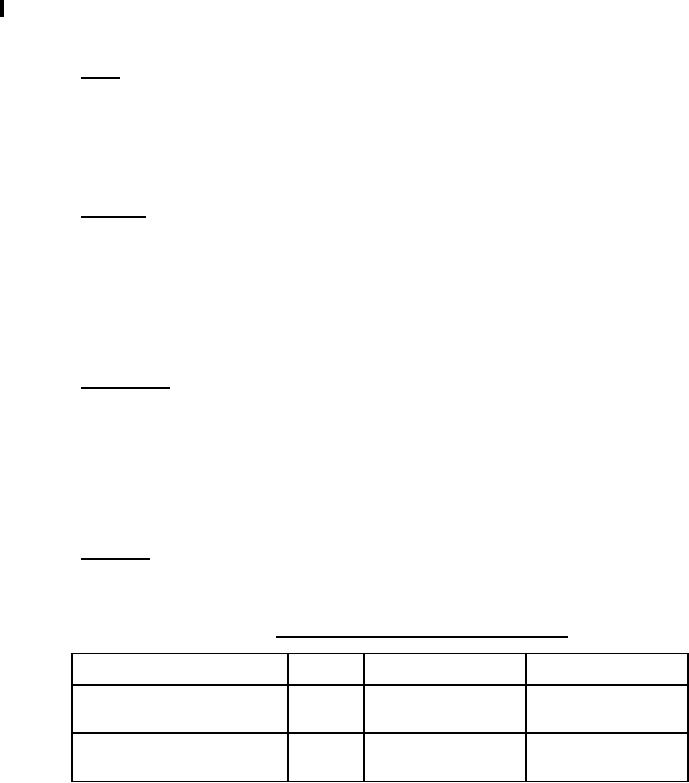

TABLE A-I. Specimens for complete qualification submission.

Quantity for complete

Qualification group

Style

Parts to be submitted

qualification groups

A (operating temperature

CH09A1RA183K

25

CH09

range -55 to +85°C)

CH09A1RA126K

25

B (operating temperature

CH09

CH09A1NC104K

25

range -55 to +125°C)

CH12

CH12A1NF225K

25

20

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business